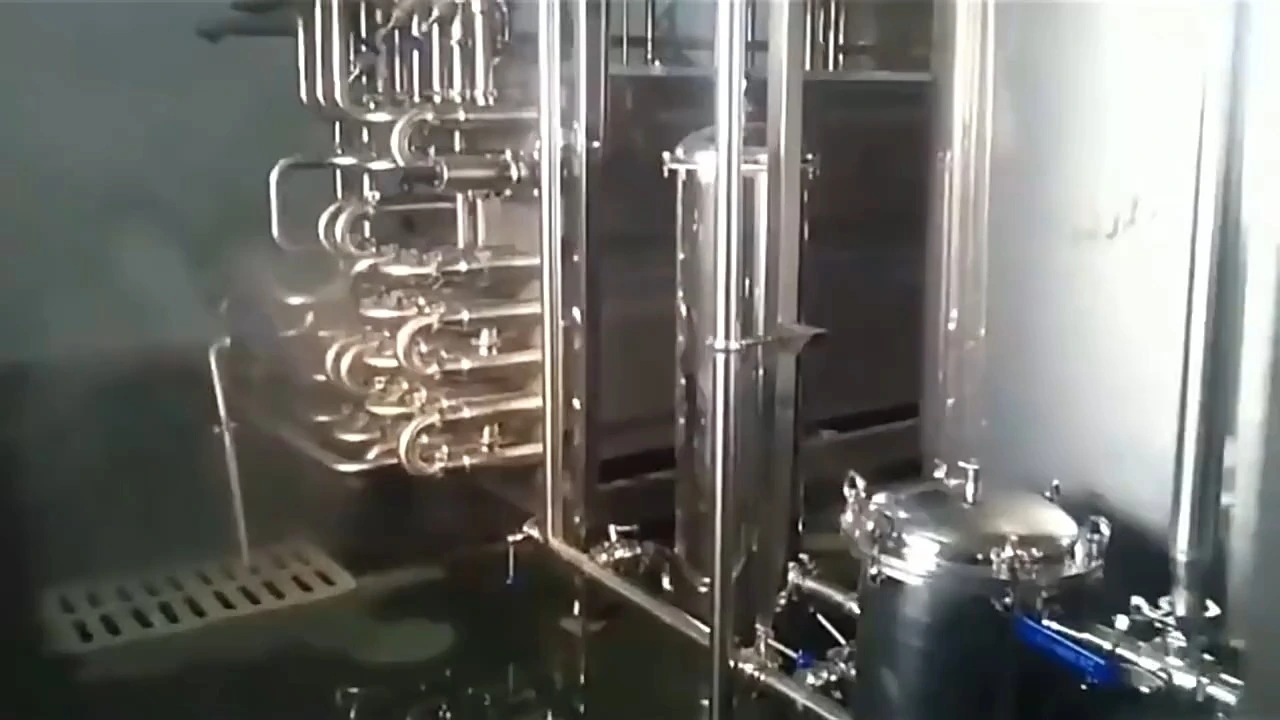

UHT Sterilizer Machine for Food Processing Tube Type Beverage Pasteurizer for Milk Juice Other Liquids

Product Description

Milk Juice And Other Liquid Processing Uht Sterilizer Machine plate type pasteurizer

Operational principle The working principle of the tube sterilization machine is to use a high-pressure pump to transport materials to a closed stainless steel pipe and heat them through a heat exchanger. The material is kept at high temperatures (usually between 138℃ and 150℃) for a certain time (generally 3 to 8 seconds) to ensure the killing of microorganisms and spores. After that, the material is cooled by heat exchange with the cold material, usually to a temperature below 65℃. This process is completed in an instantaneous time, effectively preventing the secondary contamination of food.

Features and advantages 1.Strong adaptability: The tubular sterilizer can adapt to a wide range of viscosities and can also be used for sterilizing fibers and particles. 2.Instant processing: Through high-temperature and short-term sterilization treatment, the original flavor and nutritional content of the product can be maintained. 3.High degree of automation: The entire sterilization process can be automatically controlled and recorded, equipped with a PID temperature control system that can monitor temperature in real time. At the same time, the device also has an automatic cleaning function to prevent the product from sticking to the pipeline. 4.High thermal efficiency: After heating the material, the heat recovery rate can reach over 90%, significantly reducing energy consumption. 5. High safety: The main components of the equipment are made of well-known brands and imported products, equipped with pressure protection measures and alarm systems to ensure the safety of operators and the safety of the equipment itself.

Product Description

Milk Juice And Other Liquid Processing Uht Sterilizer Machine plate type pasteurizer

Operational principle The working principle of the tube sterilization machine is to use a high-pressure pump to transport materials to a closed stainless steel pipe and heat them through a heat exchanger. The material is kept at high temperatures (usually between 138℃ and 150℃) for a certain time (generally 3 to 8 seconds) to ensure the killing of microorganisms and spores. After that, the material is cooled by heat exchange with the cold material, usually to a temperature below 65℃. This process is completed in an instantaneous time, effectively preventing the secondary contamination of food.

Features and advantages 1.Strong adaptability: The tubular sterilizer can adapt to a wide range of viscosities and can also be used for sterilizing fibers and particles. 2.Instant processing: Through high-temperature and short-term sterilization treatment, the original flavor and nutritional content of the product can be maintained. 3.High degree of automation: The entire sterilization process can be automatically controlled and recorded, equipped with a PID temperature control system that can monitor temperature in real time. At the same time, the device also has an automatic cleaning function to prevent the product from sticking to the pipeline. 4.High thermal efficiency: After heating the material, the heat recovery rate can reach over 90%, significantly reducing energy consumption. 5. High safety: The main components of the equipment are made of well-known brands and imported products, equipped with pressure protection measures and alarm systems to ensure the safety of operators and the safety of the equipment itself.