Stainless Steel Vertical Tanks: From Manufacturing to Cleaning

Understanding the Manufacturing Process of Stainless Steel Vertical Tanks

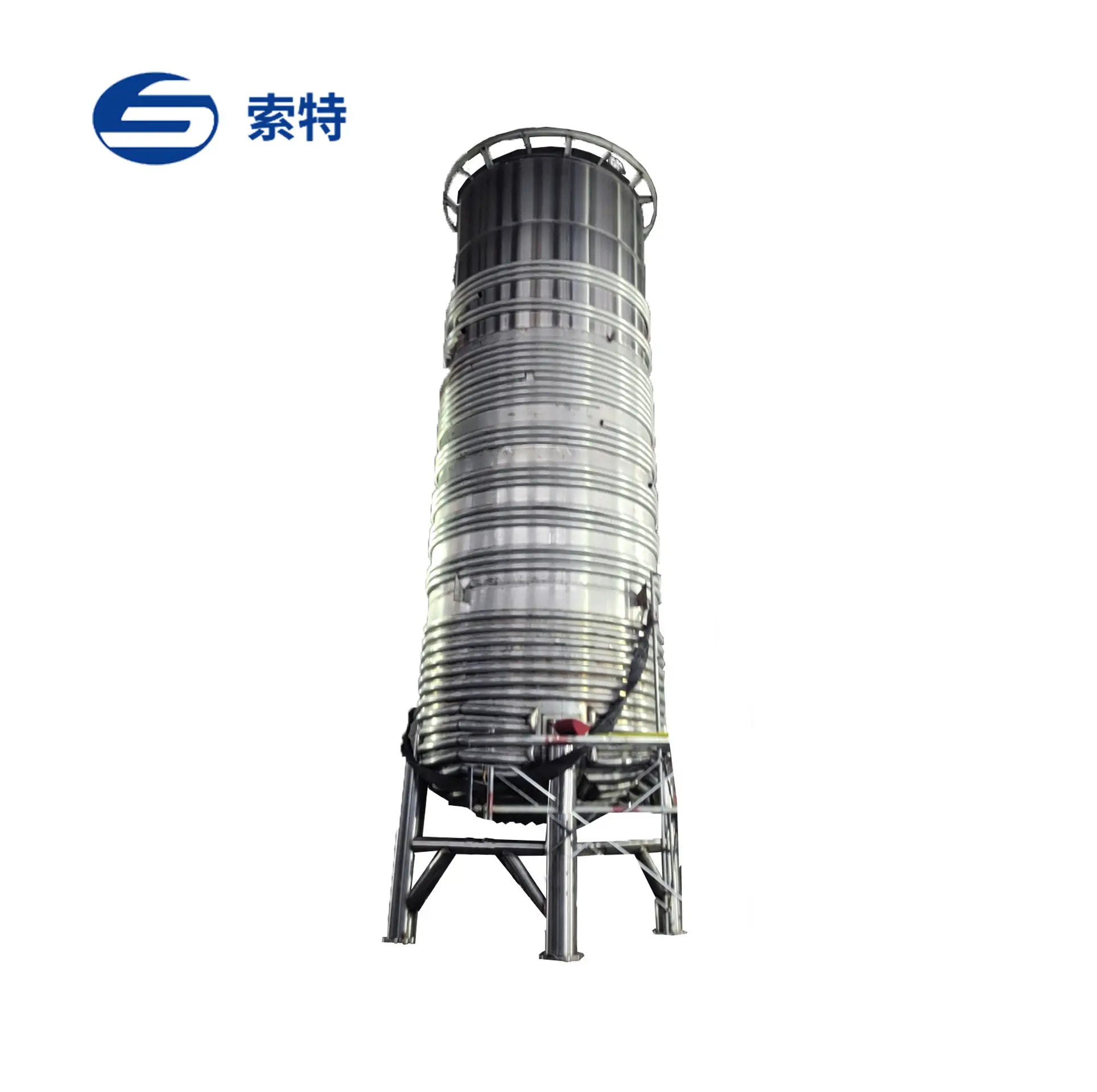

The manufacturing process of stainless steel vertical tanks is a meticulously controlled and precise operation. It begins with the selection of high-quality raw materials, such as austenitic stainless steel, which is known for its corrosion resistance and mechanical strength. Once the steel is selected, it undergoes several processing steps to ensure the final product meets the required specifications.

The first step in the manufacturing process is cutting, where the steel is precisely shaped to the desired dimensions. This is followed by forming, where the cut pieces are shaped into the desired cylindrical or rectangular structure. Welding is a crucial step, ensuring that the pieces are seamlessly joined to form a single, cohesive tank. The final stage involves finish treatment, where the tank is polished and coated to enhance its appearance and protect against corrosion. Quality control measures, such as non-destructive testing and inspections, are conducted throughout the process to ensure that the tanks meet the required standards.

Customization and Design Flexibility in Stainless Steel Vertical Tanks

Customization is a significant aspect of stainless steel tank design, allowing for tailored solutions to meet specific client needs. Tanks can be customized to different sizes, shapes, and capacities, ensuring that they fit seamlessly into existing systems. Factors such as pressure requirements, material thickness, and compliance with industry standards are considered during the design phase. This flexibility ensures that tanks can be used in a wide range of applications, from small HVAC systems to large-scale industrial water storage.

Applications and Industries Using Stainless Steel Vertical Tanks

Stainless steel vertical tanks find applications across numerous industries, each benefiting from their unique properties. In the food and beverage industry, these tanks ensure the purity and quality of products, from milk to carbonated beverages. Pharmaceutical plants rely on stainless steel tanks to maintain sterile conditions, crucial for the production of drugs and medical equipment. Water treatment facilities use these tanks to store and transport clean water, ensuring that it meets stringent safety standards. The oil and gas sector benefits from the strength and durability of stainless steel tanks, which can withstand harsh environmental conditions.

Cleaning and Maintenance of Stainless Steel Vertical Tanks

Cleaning and maintenance are critical for ensuring the hygiene and longevity of stainless steel vertical tanks. Regular cleaning processes, such as chemical or sonic cleaning, prevent corrosion and extend the tanks lifespan. Protective linings and temperature adjustments are also employed to maintain optimal conditions. Regular inspections and preventive maintenance are essential to keep tanks performing efficiently, preventing potential issues and ensuring safety.

Safety Considerations and Regulatory Compliance

Safety and compliance are paramount when using stainless steel vertical tanks. Regular inspections and adherence to safety protocols prevent accidents and ensure the protection of workers. Compliance with industry standards and regulations is essential for operational safety. Case studies of successful companies that have adhered to these standards showcase the importance of rigorous compliance practices.

Future Trends and Innovations in Stainless Steel Vertical Tanks

The future of stainless steel vertical tanks is filled with exciting trends and innovations. Technologies like 3D printing enable the creation of complex designs, while advanced coatings enhance durability. Smart systems for monitoring tank performance reduce maintenance needs, offering a sustainable solution for industries. These advancements not only improve efficiency but also reduce costs, promising a brighter future for stainless steel tanks.

In conclusion, stainless steel vertical tanks are essential in various industries, offering reliability, hygiene, and efficiency. Their journey from raw materials to application involves meticulous manufacturing, customization, and continuous innovation. By prioritizing safety and compliance, these tanks ensure optimal performance and safety. As technology evolves, the future of stainless steel tanks looks even more promising, ready to meet the demands of tomorrows industries.