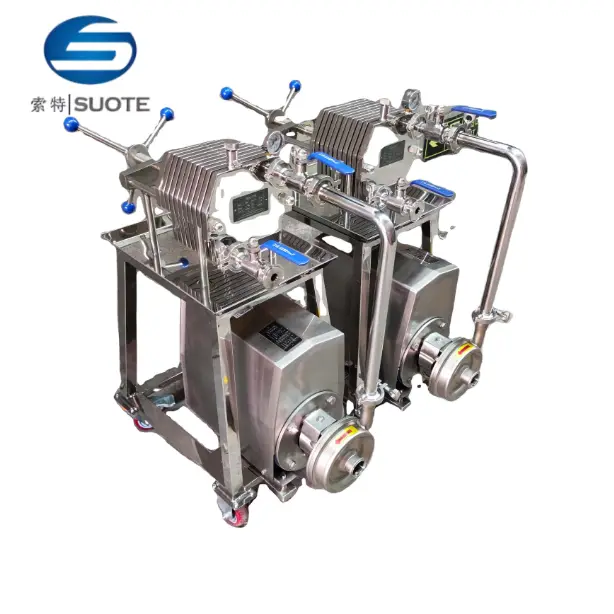

Quality Stainless Steel Filter Press Price List

Product details of the stainless steel filter press

Product Overview

Ingenious design of stainless steel filter press makes it favored by many customers. Our adherence to rigorous industry standards for quality fully guarantees that the product meets the international standards. The stainless steel filter press produced by our company is widely used. Wenzhou Suote Pharmaceutical And Chemical Engineering Co.,Ltd's well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction.

Product Description

Wenzhou Suote's stainless steel filter press has superior performances in the following details.

Purpose and advantages

1. This machine can be widely used in pharmaceutical, food, beverage, water treatment, brewing, petroleum, chemical, corrosion prevention, environmental protection and other industries, is all kinds of liquid filtration, clarification, purification, sterilization treatment of the latest equipment.

2. The use of convex filter plate, effectively increase the water cross-sectional area, reduce liquid filtration, circulation resistance, so that the liquid arbitrary flow to improper dead Angle, can maintain the stability of liquid performance, convex filter plate makes the filter material (filter film, filter paper, etc.) is not easy to damage, prolong the service life of various filter materials.

3. All sealing parts are installed (milky white silicone rubber sealing ring, non-toxic and high temperature resistance) without leakage, that is, in the front and back of the filter frame, import and export double folding ring and other sealing parts are installed with circular sealing ring.

4. The input pipe is fastened and sealed by double folding ring, with easy disassembly and cleaning.

5. This machine can according to the different production process of the filtered liquid (primary filter, half fine filter, fine filter) requirements, replace different filter material users can reduce or increase the filter box filter material according to the size of the production flow, so that widely adapt to the production needs.

6. When the filter works, press the sealing ring, the material liquid has no loss, and the liquid clarity is good. The microporous filter film is used for sterilization, and the sterilization effect is especially good.

Plate and frame filter components

Thin film filter material

Mixed cellulose ester microporous filter membraneThe microporous filter membrane made of mixed cellulose is widely used by relevant units for many times, and the quality meets the standard. The product surface is smooth, light texture, high porosity, and the microporous structure is uniform, so it has the characteristics of fast flow rate and not easy to absorb.

This product is used in pharmaceutical industry, production products, mineral spring drinks, brewing, watches and other industrial water quality, pharmaceutical oil, lubrication oil, fuel oil and scientific research laboratory and other filter bacteria and particles, generally 0.65 micron can remove particles, 0.45 can remove bacteria.(This filter membrane belongs to the terminal filter membrane).

The mixed cellulose ester microporous filter membrane has various specifications as described belowdiameter mm: 25 35 50 60 100 150 200 300 400 200x200 300x300 400x400aperture um: 0.2 0.3 0.45 0.65 0.8 1.0 1.2

For special specifications, additional customization.

Usage method:1.Put the filter film flat in the cleaning container, soak it with distilled water of about 70 degrees, and wet it all. After a few hours (about 4 hours), soak it overnight, and soak it with appropriate amount of warm distilled water before use. 2.Put the cleaned filter film (wet) into the appropriate filter to prevent leakage in the surrounding night, put the filtrate into the liquid inlet, and remove the air from the exhaust air, can be filtered.

matters need attention:1.Water diaphragm is suitable for pH 2-9 liquid, which is not suitable for strong acid and base or organic solvents including alcohol.

2.This product is generally 130 degrees, pressure 3-4 kg / cm 2

3.The microporous filter film can only be filtered as the final stage, and the filtrate must be pre-filtered through the plate and frame or other filter materials to avoid the blockage of the filter film.4.The method used above: applicable only for the filtration of aqueous agents or other aqueous solvents.

Product parameters

|

type |

number of plies (flat) |

filter area(m2) |

filter size(mm) |

filter membrane aperture(um) |

filter pressure(Mpa) |

water flow(T/h) |

power of motor (Kw) |

external size(mm) |

|

WBG-1-100 |

10 |

0.078 |

Φ100 |

0.8 |

0.1 |

0.8 |

0.55 |

600*290*630 |

|

WBG-1-150 |

10 |

0.170 |

Φ150 |

0.8 |

0.1 |

1.5 |

1.1 |

700*330*680 |

|

WBG-1-200 |

10 |

0.314 |

Φ200 |

0.8 |

0.1 |

3.0 |

1.1 |

790*380*750 |

|

WBG-1-300 |

10 |

0.706 |

Φ300 |

0.8 |

0.1 |

5.0 |

1.1 |

850*460*920 |

|

WBG-1-400 |

10 |

1.250 |

Φ400 |

0.8 |

0.2 |

8.0 |

2.2 |

1050*690*1150 |

|

WBG-1-400 |

16 |

2.000 |

Φ400 |

0.8 |

0.2 |

9.0 |

2.2 |

1250*690*1200 |

|

WBG-1-400 |

20 |

2.500 |

Φ400 |

0.8 |

0.2 |

10.0 |

2.2 |

1350*690*1200 |

|

WBG-1-400 |

24 |

3.000 |

Φ400 |

0.8 |

0.2 |

11.0 |

2.2 |

1450*690*1200 |

|

WBG-1-400 |

32 |

4.000 |

Φ400 |

0.8 |

0.3 |

13.0 |

3.0 |

1550*690*1200 |

|

WBG-1-400 |

40 |

5.000 |

Φ400 |

0.8 |

0.3 |

15.0 |

3.0 |

1650*690*1200 |

|

WBG-1-400 |

48 |

6.000 |

Φ400 |

0.8 |

0.3 |

19.0 |

3.0 |

1750*690*1200 |

|

WBG-1-400 |

56 |

7.000 |

Φ400 |

0.8 |

0.3 |

23.0 |

3.0 |

1850*690*1200 |

Operating Procedures

product display

Company Information

Wenzhou Suote Pharmaceutical And Chemical Engineering Co.,Ltd, short for Wenzhou Suote, insists on providing customers with safe The main products include tanks like fermentation tanks,TK tanks,powder tanks,mechanical or magnetic stirring dosing tanks,extraction tanks,stainless steel reactors,concentrators and other tank equipment,heat exchange equipment such as column and tube heat exchangers,PLC control systems,various types of filters and purification area dedicated to various types of pipes,fittings,clamps and diaphragm valves,tank bottom valves and other engineering supporting products. Customers can rest assured during the purchase. Based on the belief of 'only by working hard can we survive' and 'customers are the center', Wenzhou Suote insists on taking quality and innovation as the starting point of enterprise development, and strives to become a world-class company with international competitiveness. Wenzhou Suote has established a professional marketing team with consumer demand as the core. This has promoted market expansion both at home and aboard and has provided a strong guarantee for the constant supply of high-quality products. Wenzhou Suote insists on providing customers with comprehensive solutions based on their actual needs, so as to help them achieve long-term success.

Our products are of guaranteed quality and tight package. Welcome customers with needs to contact us!