Wenzhou Suote Dairy Lines with Custom Services

Milk processing production line

Milk processing production line is the core part of the dairy processing industry, which integrates modern technology and strict hygiene standards to ensure the purity, safety and nutrition of milk.

Technical feature

◆ Highly automated: the whole production line adopts highly integrated automation equipment to reduce human contact, improve production efficiency and ensure food safety.

◆ Strict quality control: from raw material acceptance, pretreatment to finished product storage, every link of strict quality control, to ensure the purity and safety of products.

◆ Retain natural nutrition: adopt advanced sterilization and homogenization technology to retain the natural nutrition and flavor of milk to the maximum extent, to meet consumers' pursuit of healthy dairy products.

Process flow

The process of milk processing production line mainly includes raw material acceptance, pretreatment, standardization, sterilization, homogenization, cooling, packaging and storage of finished products.

Raw material acceptance: conduct strict quality inspection of the purchased fresh milk to ensure that it meets the production requirements. The main examination indicators include milk fat rate, milk protein rate, the total number of bacteria, etc.

Pretreatment: the qualified raw milk should be filtered and removed to remove impurities and bad ingredients.

Standardization: According to the product requirements, standardize the pretreated milk to adjust its milk fat rate and milk protein rate to the specified range.

Sterilization: using pasteurization or ultra-high temperature instantaneous sterilization method to sterilize milk, kill the harmful bacteria in milk, to ensure the health and safety of products.

Homogenization: The sterilized milk is treated by a homogenizer to improve the taste and stability of the product.

Cooling: the homogeneous milk is quickly cooled to the appropriate temperature to inhibit bacterial reproduction and extend the shelf life of the product.

Packaging: Aseptic packaging technology is used to fill and seal the cooled milk to ensure the health and safety of the products during transportation and storage. Packaging materials are diverse, can choose environmentally friendly and can .

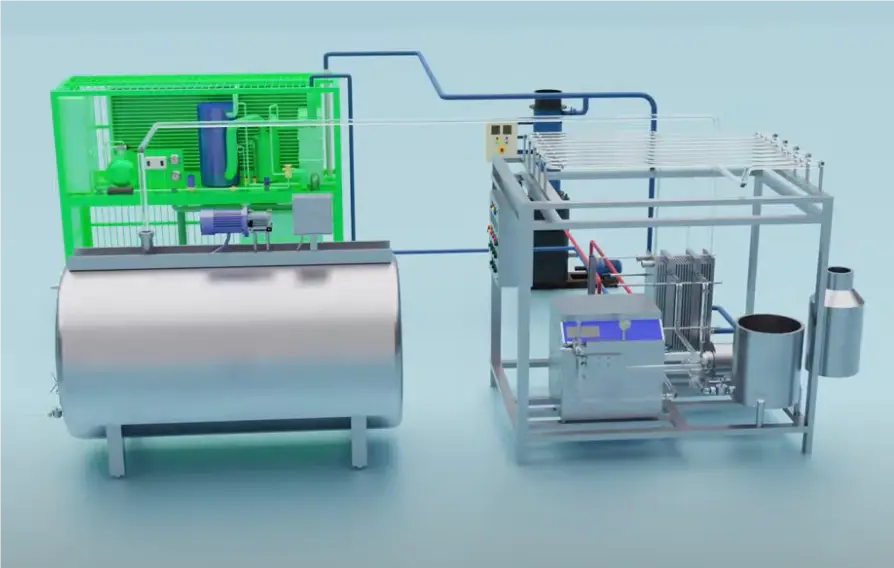

Production line composition

Milk processing production line is mainly composed of a series of key equipment, including refrigeration tank, pasteurization tank, pre-cooling tank, double filter, homogenizer, etc. These devices play a crucial role in the processing of the milk.

video

The yogurt production line

Yogurt processing production line is a crucial link in the dairy processing industry. It combines modern technology with strict quality control standards to ensure the purity, safety and nutrition of yogurt products.

Technical characteristics and advantages

Production flow

The production process of yogurt processing production line mainly includes raw material acceptance, pretreatment, sterilization, cooling, inoculation of lactic acid bacteria, fermentation, filling, cooling and storage, packaging and transportation. These links connect with each other, and together constitute a complete yogurt production process.

Production line composition

The yogurt processing production line is mainly composed of raw material processing system, fermentation system, filling system, cooling and storage system, and packaging and delivery system.

Packaging and Delivery System

Final Product

Company Advantages

· Wenzhou Suote dairy lines is designed by our designers who are actively developing new products based on the spirit of innovation.

· The product is of reliable quality because it is manufactured and tested in accordance with widely recognized quality standards.

· This product has received many positive feedback for its huge economic effectiveness from customers at home and abroad.

Company Features

· Wenzhou Suote manufactures high quality dairy lines that exceed industry standards.

· We recently imported a series of advanced production facilities. This empowers us to manufacture products at the highest level and speed and meet exacting specifications.

· We adhere to the brand building, independent innovation as the driving force of development. We will put more investment in R&D to enhance our product creativity.

Application of the Product

The dairy lines of Wenzhou Suote can be used in many industries.

Through problem analysis and reasonable planning, we provide our customers with an effective one-stop solution to the actual situation and needs of customers.