Long Lasting Chemical Manufacturing Equipment Chemical Manufacturing Equipment Company

Product details of the chemical manufacturing equipment

Quick Detail

Our focus on the details during the production makes Wenzhou Suote chemical manufacturing equipment impeccable in details. The product has been inspected in conformity with international quality standards. The chemical manufacturing equipment produced by our company is suitable for various occasions in industry. The product, even in the fierce market competition, has won wide recognition in the market and has a bright application prospect.

Product Description

Next, Wenzhou Suote will show you the details of chemical manufacturing equipment.

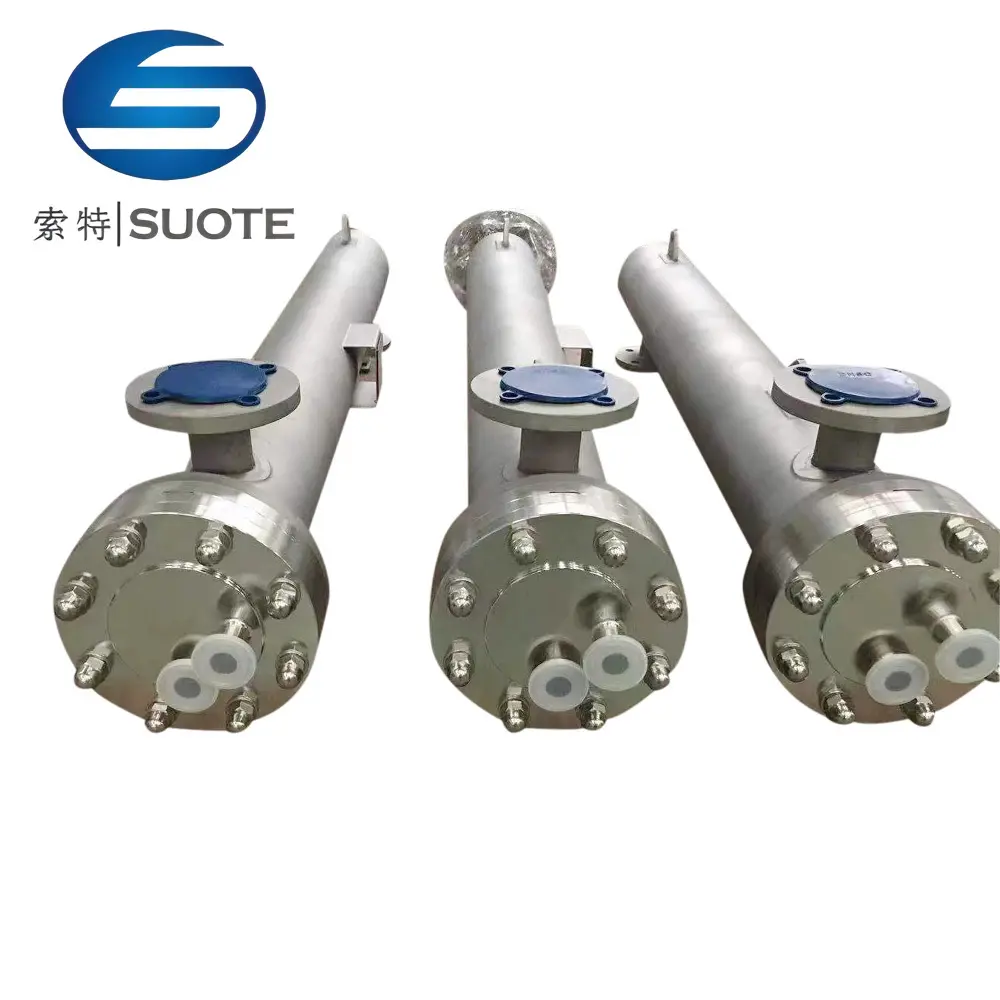

Tubular heat exchanger

Double tube sheet heat exchanger

Double tube sheet heat exchanger has a simple structure and reliable .adaptable ,cleaning more convenient .large capacity ,able to withstand high temperature and high pressure etc .no dead ends in the heat exchanger .pollution ~ free .easy to clean .small footprint ,easy to install .is the mature technology .heat transfer equipment standardization .comply with chemical industry is an ideal heat transfer equipment .Imported 316L production heat exchanger inside the tube speciations

∅9.53*1.0mm

The inner surface of the electro-chemical polishing ,roughness Ra0.2um

EPE insulation ,the outer surface 304 matte board of drawing processing .

4.the heat transfer area : 1. 1.5 ,2,2.5,3 m2

Maximum operating pressure : 1.0 MPa

Maximu operating temperature 150℃

Heat transfer coefficient : water -water : 1100~1400W/(m2 ℃)

Water -steam : 2300~5700/ (m2 ℃)

Installation diagram of coiled tube heat exchanger

Running way of Double tube sheet heat exchanger

Double tube shoet heat exchanger has a simple structure and reliable. Adaptable, cleaning more convenient, large capacity,able to withstand high temperature and high pressure,etc.

Ideal tube type heat exchanger

No dead ends in the heat exchanger,pollution-free.easy to clean,small footprint,easy to installIs a mature technology,heat transier equipment standardization Comply with the GDP the requirements of the chemical industry,the chemical industry is an ideal heat transfer equipment.

Technical Information

|

Volume (L) |

Core Dia. (mm) |

Jacket Cover dia (mm) |

Motorpower (KW) |

Working pressure (MPa) |

Speed RPM |

Vacuum (MPa) |

Working temperature (℃) |

|

30 |

400 |

500 |

0.6-1.1 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

50 |

500 |

600 |

0.6-1.1 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

100 |

550 |

650 |

1.1-1.5 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

150 |

600 |

700 |

2.2 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

200 |

650 |

750 |

2.2 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

300 |

2050 |

110 |

3 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

500 |

900 |

1000 |

4 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

800 |

1100 |

1200 |

5 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

1000 |

1200 |

1300 |

6 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

1500 |

1300 |

61400 |

4 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

2000 |

1400 |

1500 |

4 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

2500 |

1400 |

1500 |

7.5 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

4000 |

1500 |

1600 |

7.5 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

8000 |

2000 |

2100 |

15 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

|

32000 |

3000 |

2100 |

37 |

homoeothermy |

51-35 |

< - 0.09 |

0~100 |

Product display

Company Introduction

Located in wen zhou, Wenzhou Suote Pharmaceutical And Chemical Engineering Co.,Ltd is a professional company. We have main products including The main products include tanks like fermentation tanks,TK tanks,powder tanks,mechanical or magnetic stirring dosing tanks,extraction tanks,stainless steel reactors,concentrators and other tank equipment,heat exchange equipment such as column and tube heat exchangers,PLC control systems,various types of filters and purification area dedicated to various types of pipes,fittings,clamps and diaphragm valves,tank bottom valves and other engineering supporting products. Our company always insists on the business philosophy of 'winning the market with quality and gaining the reputation with service'. All of us should struggle hard to achieve development step by step, and pursue excellence and innovation in a practical and diligent attitude. All that brings us a brand new attitude, leading our company's development. In recent years, Wenzhou Suote selected and trained outstanding talents from many well-known institutions at home and abroad, who are of great importance to our talents team. This makes a contribution to our company's sustainable development. Our company will modify and adjust the original solution according to the customer's needs. By doing so, we can provide solutions that best meet the customer's needs.

If you have needs for purchasing our products in bulk, please contact our official customer service personnel.