Stainless Steel 304L/316L Sanitary Centrifugal Pumps

Application:

Sanitary centrifugal pump is widely used in the delivery of various solutions, such as dairy, beer, beverage, medicine, raw Material engineering, fine daily use chemical industry field. The pump is a single suction single stage, centrifugal sanitary pump. Pump shell, impeller meridian Heart design, small resistance, completely eliminated the health dead corner. So it improves the flow rate of the liquid in the pump High overall performance of the pump, and easy to clean, easy disassembly, has excellent sanitary performance, it can meet the production The requirements for sanitary flexible treatment, and have chemical corrosion resistance.

Composition and structural characteristics

Sanitary centrifugal pumps are mainly composed of pump body, pump cover, impeller, mechanical seal, motor and other parts. The design adopts a sleek, rigid structure and thick wall design. Each part is connected by bolts. There are four adjustable support feet under the base plate for easy installation without the need for a fixed installation foundation. During installation, the outlet pipe can be installed in a vertical or horizontal direction according to different needs.

The mechanical seal of the centrifugal pump is customized with imported high-quality stainless steel and silicon carbide, which greatly improves the wear resistance and self-lubricating properties and extends the service life. During production, the pump body and impeller are precision cast as a whole, and all parts are surface treated. Special fixtures are used to ensure dimensional clearance during installation.

The shaft seal adopts an open structure, so even if there is a small amount of leakage at the shaft seal, it can be detected in time. Even if it is not noticed in a short period of time, it will not overflow into the motor, thus ensuring the service life of the motor.

This series of pumps are finely made and not easy to scale, especially suitable for CIP cleaning.

This series of pumps has a simple structure, easy disassembly, low noise, high efficiency, gentle and gentle material handling, meets food hygiene requirements and ensures the original flavor of the product.

Centrifugal pump components

| SIZE mm |

POWER Kw | ||||||||||

| 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | |

| A | 265 | 305 | 305 | 320 | 320 | 375 | 375 | 425 | 425 | 555 | 555 |

| B | 199 | 244 | 244 | 244 | 244 | 284 | 284 | 344 | 344 | 374 | 374 |

| C | 112 | 125 | 125 | 140 | 140 | 160 | 190 | 216 | 216 | 254 | 254 |

| D | 160 | 208 | 208 | 208 | 215 | 240 | 240 | 330 | 330 | 430 | 430 |

| E | 65 | 57 | 57 | 71 | 71 | 74 | 74 | 67 | 67 | 68 | 68 |

| F | 49.5 | 61.5 | 61.5 | 70 | 70 | 83 | 83 | 91.5 | 91.5 | 101.5 | 101.5 |

| G | 131 | 135 | 135 | 162 | 162 | 173 | 173 | 176 | 176 | 207 | 207 |

| H | 437.7 | 481 | 481 | 516 | 516 | 573.5 | 573.5 | 650 | 650 | 803.5 | 803.5 |

| I | 35.3 | 81 | 81 | 110 | 102.5 | 113 | 113 | 105 | 105 | 116 | 116 |

| J | 136 | 155 | 155 | 165 | 165 | 175 | 187 | 217 | 217 | 265 | 265 |

| K | 275 | 290 | 290 | 330 | 330 | 370 | 370 | 430 | 430 | 545 | 545 |

1. Pump body

2. Shaft cap

3. Impeller

4. Mechanical sealdynamic ring

5. Pump body o ring

6. Mechanical seal static ring

7. Impeller seat

8. Static ring seat

9. Spring

10. Retainer ring

11. Snap spring

12. Namepla te

13. Support

14. Pump shaft

15. Straining ring

16. Staining sleeve

17. Motor

18. Pump foot

19. Housing

Product parameters

|

Type |

Centrifugal Pump |

|

Product name |

Sanitary Centrifugal Pump |

|

Material |

Stainless Steel 304L/316L |

|

Horsepower |

0.75kw/1.5kw/2.2kw/5kw etc |

|

Size |

437.7-803.5mm*199-374mm*165-555mm |

|

Max.Head |

>150m |

|

Max.Capacity |

200-300 L/min |

|

Working Pressure |

Middle Pressure Pump |

|

Usage |

Dairy,food,beverage,cosmetic |

|

Voltage |

220V-480V |

|

Exit size |

DN40 OR Customizable |

Materials and Technical Parameters

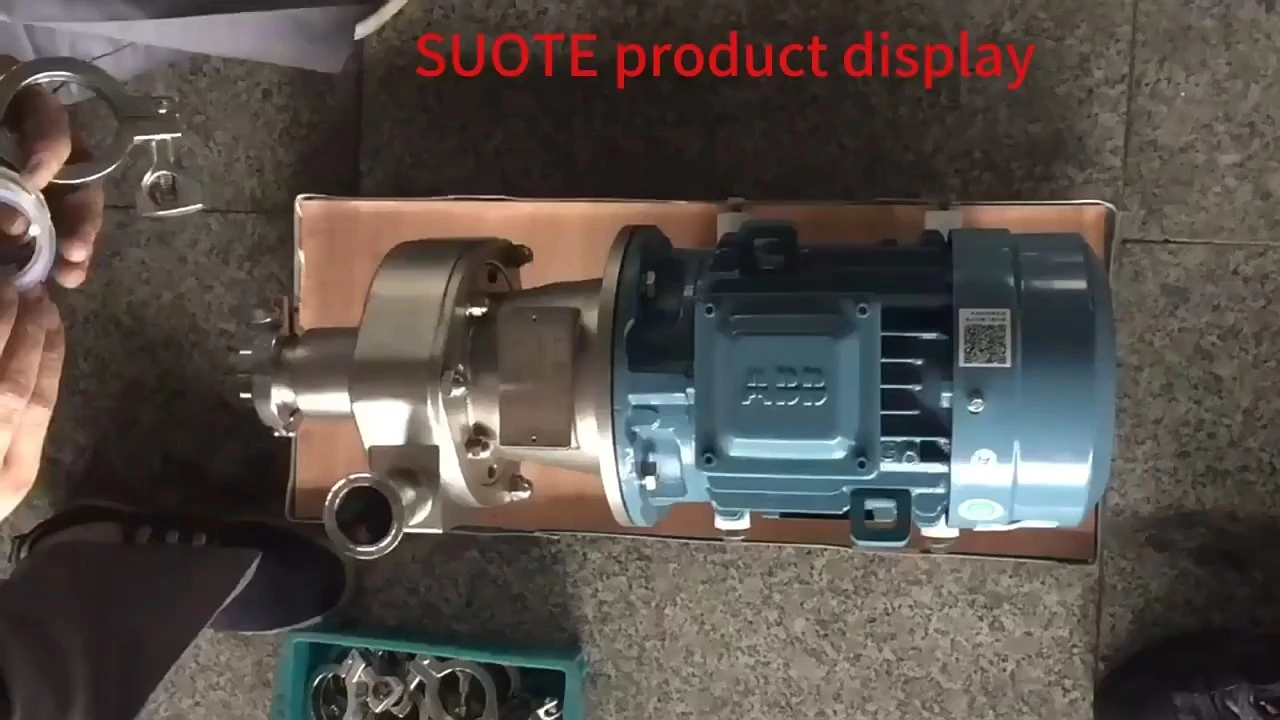

product display